Benefits at a glance

Convincing arguments

High crushing capacity and lower

High crushing capacity and lower

operating costs

Powerful rotors and robust

Powerful rotors and robust

baffle plates

Maintenance-friendly design for quick access to the

Maintenance-friendly design for quick access to the

access to the maintenance units

Optimal customization and adaptation

Optimal customization and adaptation

for your material

The latest impact crusher generation

The most versatile impact crusher for all applications

Due to the development of new impact bars and geometries in the machines, impact crushers are finding more and more new fields of application. In Europe, it is impossible to imagine recycling without the impact crusher and it is the most frequently used machine for separating mineral products and metals. These can be, for example, ferrous concrete components, steel slags from blast furnaces or IBA for the recovery of non-ferrous metals (NF metals). Not only the separation plays a decisive role, but also the subsequent properties of the end products in terms of pressure load, particle shape and purity. All impact crushers are customized with a wide range of built-in parts and thus designed for customer-specific applications. Many machines look similar, but the essence is in the details and in the experience gained from 4 decades of crusher construction.

One impact crusher - many possibilities

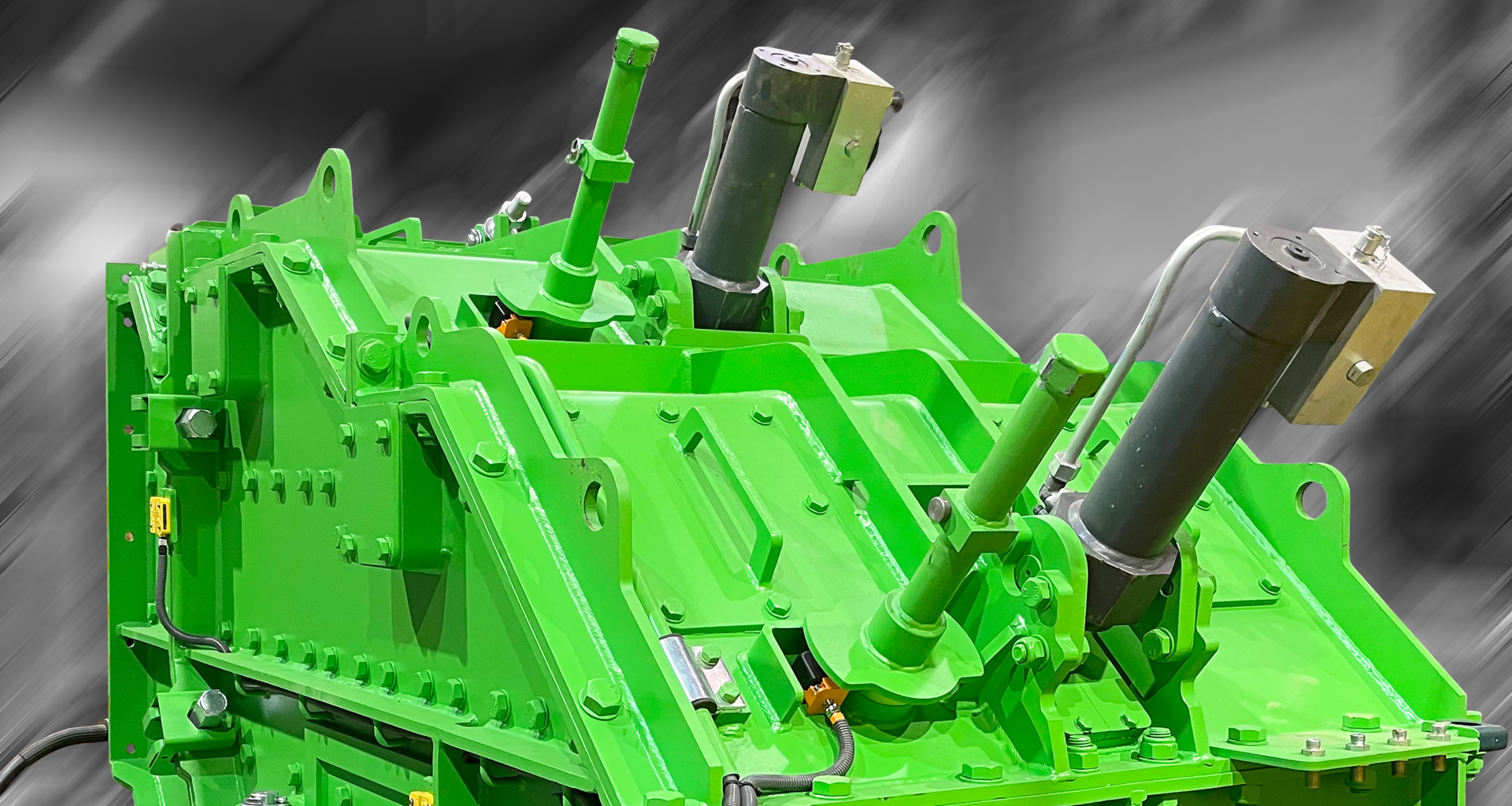

PT 110-100 - A new and compact generation of impact crushers

| Throughput per hour: | Weight: | Feed opening: | Inlet size: | Power direct drive: | Final grain: |

| Up to 200 t | 8700 kg | Up to 700 mm | 770 mm x 1020 mm | 200 kW | 0-10 mm (Grinding path) |

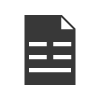

With the new PT 110/100, we would like to introduce the advantages and innovations of the current PT series. With the new models we can use a fully hydraulic impact plate adjustment or a conventional spindle technology and also remove each impact body individually with a screw-on housing cover to change the impact plates safely and quickly. Another innovation is the integrated inlet into the crusher, which saves a lot of space in mobile machines or skid frame units. The innovative housing design also allows us to build a more space-saving impact crusher with the same rotor size. Even with the smaller outer dimensions, there are no restrictions on the passage opening for foreign material or the throughput per hour. In addition, all PT impact crushers can be expanded with optional grinding bars. This quickly turns a primary crusher into a secondary crusher for the production of grit or the optimal separation of IBA.

Construction waste recycling with the PT 130-130 impact crusher

We make your ideas come true

From the idea, through planning and design, to construction and assembly, we offer plant engineering from a single source. The machine parts are manufactured in our own production facility in Lengerich and thus form a high-performance unit together with the impact mill according to your specifications and wishes. The knowledge and experience is reflected in each plant and thus individual components are perfectly matched to each other and ensure a good interaction of all installed machines. Whether a small secondary crusher with steel structure, a crusher station with feed unit and pre-screen or a complete plant with impact crushers, vibrating feeders, screening machines and conveyor belts – we realize your ideas and contribute our knowledge for a perfect solution.

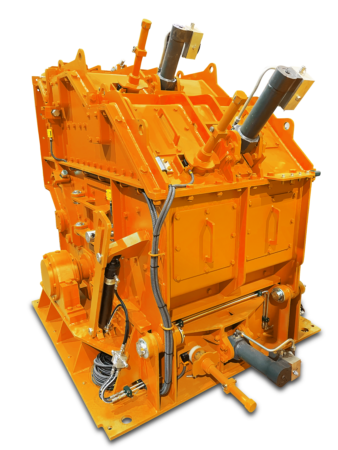

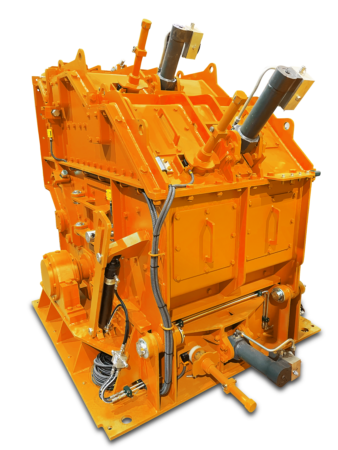

Rotor technology

The heart of every impact crusher

Every rotor goes through a special manufacturing process at Prall-Tec, which is designed for the toughest applications and has been continuously developed for decades. The heart of any impact crusher is the rotor, so this is where the most effort should be made to make our customers’ subsequent work as easy as possible. All rotor parts are made of hardened steel or forged parts. This ensures that no cracks can form in the rotor body, which is prevented not least by our welding and temperature process. The bearing housings and labyrinths are also manufactured in-house to withstand the impact of foreign objects inside the crusher and also ensure a long service life for the spherical roller bearings. This rotor, combined with state-of-the-art impact bars and ceramic inserts, ensures maximum run times and consistent high production.

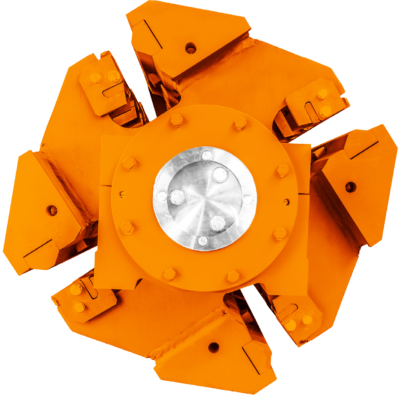

The PT impact mill and spindle technology

Various options for setting the end product sizes

Areas of application of the impact crushers

Your material - Our impact crushers

Impact crushers

Impact crushers

Reversible impact crushers

Reversible impact crushers

Fine grinding mills

Fine grinding mills

Hammer mills

Hammer mills

Shredder

Shredder

Rotary shears

Rotary shears

Balling mills

Balling mills

Mobile crushers

Mobile crushers

Stationary recycling systems

Stationary recycling systems

Rotors

Rotors

Screening machines

Screening machines

Vibrating feeders

Vibrating feeders

Recyglass®

Recyglass®

Used machines

Used machines

Rental machines

Rental machines

Construction waste

Construction waste

Glass

Glass

Slags/IBA

Slags/IBA

Metals

Metals

Electronic scrap

Electronic scrap

Batteries

Batteries

Concrete

Concrete

Asphalt

Asphalt

Natural stone

Natural stone

Tires

Tires

Special solutions

Special solutions